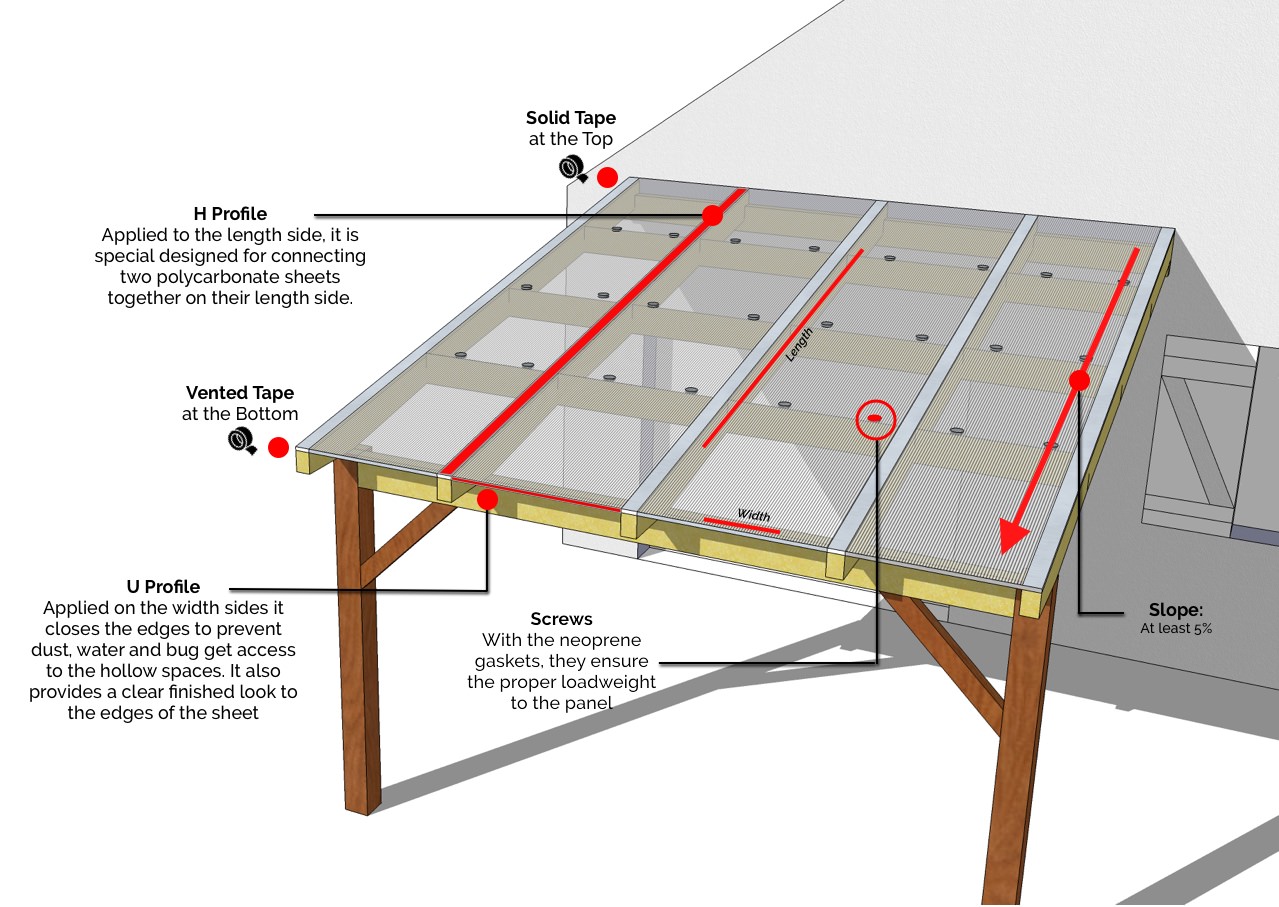

Fix the sheet through the crests for roofing with laserlite one shot fixings and through the valleys for walls with laserlite fixings for cladding or laserlite standard fixings.

How to install laserlite roofing.

Use a 10mm drill for sheets up to 4 2mm long and a 12mm drill for sheets longer than 4 2mm.

Allow an overhang of 50mm.

For roof laying start with the lower sheets first keeping side laps away from prevailing wind.

Laserlite one shot fixings are compatible with laserlite polycarbonate roofing.

Cutter engages polycarbonate sheet cuts the expansion hole and centres the screw.

Wait until the rubber weather seal engag es and compresses against the roof sheet and under the.

Secure the two bars using a rubber mallet.

Screw engages in timber or steel batten.

Any failure of the sheet due to fixings other than laserlite brands will not be covered by your warranty.

Commence drilling at 1000rpm timber one shot 2000rpm steel one shot to pierce the sheet.

For roof laying start with the lower sheets first keeping side laps away from prevailing wind.

Place the sheet between the secured glazing bars.

Allow an overhang of 50mm.

Fix the sheet through the centre of the pre drilled holes perpendicular to the purlins battens.

Sheet through the crests for roofing with laserlite one shot fixings and through the valleys for walls with laserlite fixings for cladding or laserlite standard fixings.

Only tighten the fixings enough to prevent rattling.

Use only laserlite brand fixings and weatherseals when installing laserlite polycarbonate roofing as they are designed to be compatible.

A 5 16 drill hex driver bit should be used.

Allow an overhang of 50mm.