To control the bow try using straightness applied to your sheet metal gauge thickness feature of size.

How to note flatness sheet metal drawings.

A bend table lists propertied of all bends in a flat pattern view of a sheet metal part.

For door panels front panels interior panels and racks see document 10 1006 for information on adding a note regarding the implementation eps 121.

The flatness control c defines how much a part s surface may deviate from its perfect flat form.

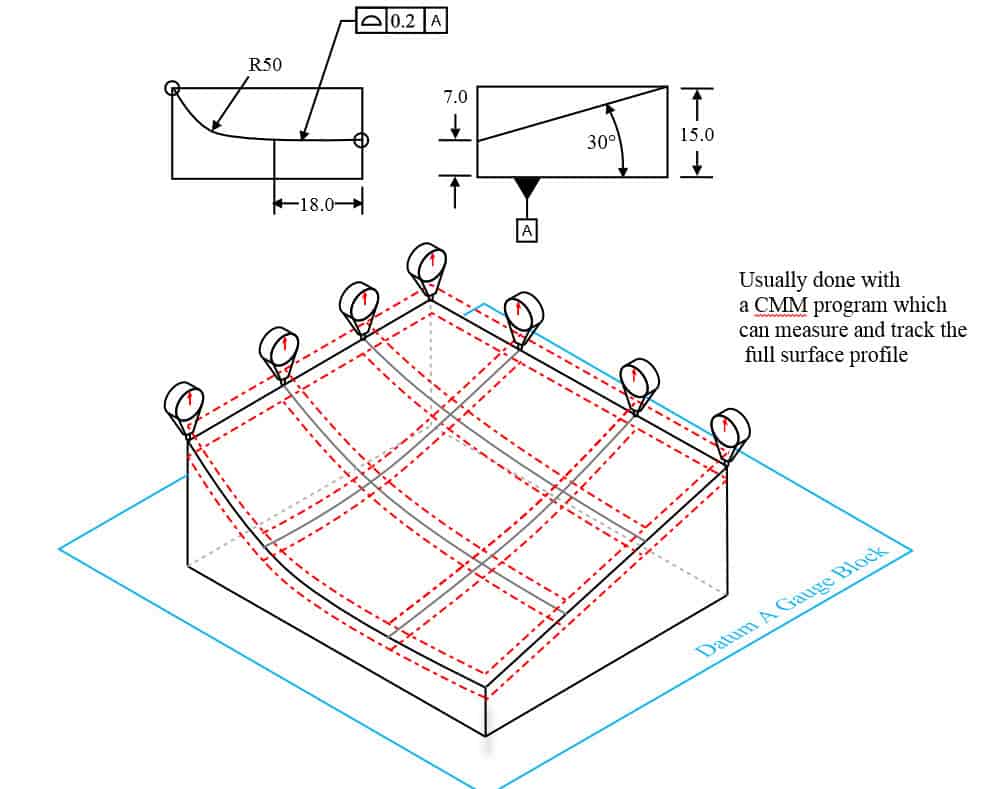

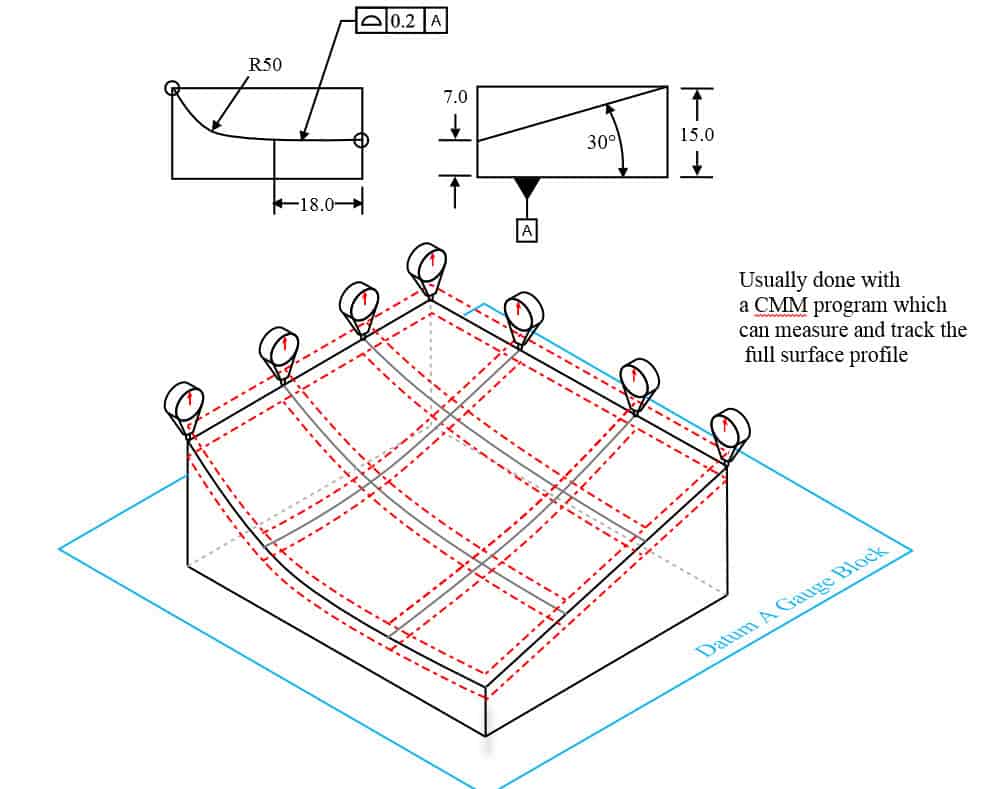

The left figure shows the drawing callout.

Unless you need the part to have a flatness that is better than the sheet metal gauge tolerance.

Yes new in 2009 drawing callout.

Although notes on each drawing will differ the first note on all sheet metal drawings that contain bends should be as follows.

Flat pattern drawing views can display bend line notes or bend tables.

Perfect flatness is when all points of a surface lie in the same plane.

It is a common symbol that references how flat a surface is regardless of any other datums or features.

Dimensions given on a flat pattern are affected by several bending factors like k factor and bend radius during the 3d modeling stage.

It comes in useful if a feature is to be defined on a drawing that needs to be uniformly flat without tightening any other dimensions on the drawing.

No mmc or lmc applicable.

Creating drawings of flat patterns.

Flatness is a form control.

The flatness control c defines how much a surface on a real part may vary from the ideal flat plane.

I don t put any standard notes on my sheet metal drawings.

After you insert the bend table in the drawing bend tags are added to the selected drawing view automatically.

Toggling the visibility of bend lines.

Bend tags associate rows in a bend table with the view geometry.

I am apply my dimensions carefully so that they are unambiguous.

Sheet metal bend line notes.

The boxed symbols can be read this surface must lie between two parallel planes spaced 0 2 apart in all views the right figure shows a possible actual part condition.

Minimum bend reliefs allowed.

Bend tags are formatted by the dimension style and do not have a leader by default.

Toggling the visibility of bend region lines.

I have read up on and taken a course on the asme y14 5m 1994.

I systematrically specify bend radii on my drawings and i include details showing what the bend corners look like before bending.

Bending factors affect the flat pattern.

The flat pattern drawing doesn t always list these factors.

Gd t flatness is very straight forward.

Toggling the visibility of sheet metal bend notes.